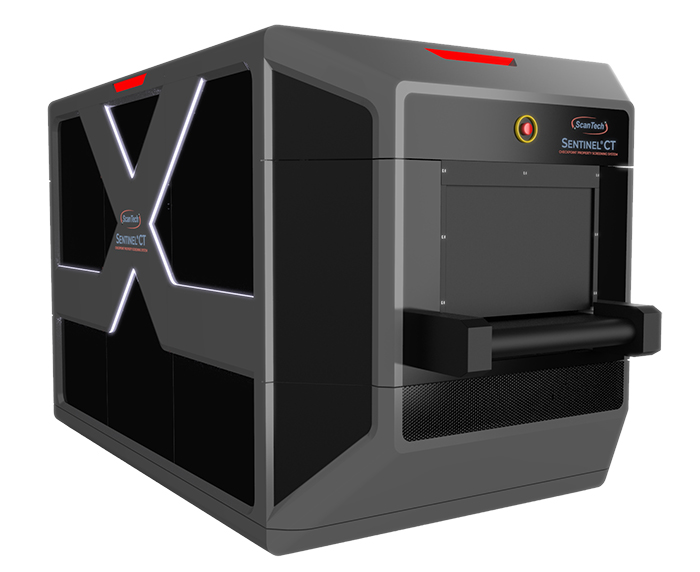

SENTINEL® CT

The SENTINEL® CT

INTELLIGENT, HIGH-SPEED, RELIABLE, EFFECTIVE AND EFFICIENT!

INTELLIGENT, HIGH-SPEED, RELIABLE, EFFECTIVE AND EFFICIENT!

Key Differentiation — Fixed-Gantry vs. Rotating-Gantry CT

Fixed-Gantry CT technology provides top tier performance and minimized total cost of ownership (TCO).

Fixed-Gantry

Faster, More Durable, Lower TCO

- Fixed-Gantry CT scanners remain static as objects are processed via conveyor belt

- Throughput is only limited by computing power

- Utilizes 120VAC single phase electrical service, enabling universal compatibility at global facilities

- Fixed-Gantry CT four-plane architecture provides high definition 3D images

- Lack of mechanical motion and multiple moving parts increases reliability and minimizes maintenance expense

Rotating Gantry

Slower, Higher Maintenance, Higher TCO

- Adopted from systems developed in 1972 for medical use

- Throughput is severely limited — to increase throughput, rotational speed must continually increase

- Intense rotation requires reinforcement of the floor at the site

- High rotational speeds can cause data loss and pose safety risks

- Moving parts require frequent downtime and high maintenance costs

SENTINEL® CT

ScanTech recognizes the need to provide superior technology in order to improve the checkpoint experience. Our systems are designed with the most exceptional level of efficiency and effectiveness for airports and other security applications. SENTINEL® CT systems are tailored to optimize threat and contraband detection while reducing false alarms leading to fewer traveler interruptions and a more expedited passenger experience.

Checkpoint baggage screening systems must be highly accurate, easy to integrate, easy to operate, easy to maintain and cost-effective. SENTINEL® CT exceeds these goals and objectives for both passengers and checkpoint operators. Our X-ray technologies are scalable and constructed to detect emerging threats with tomorrow’s technology.

SENTINEL® CT

Check Point Baggage Inspection System

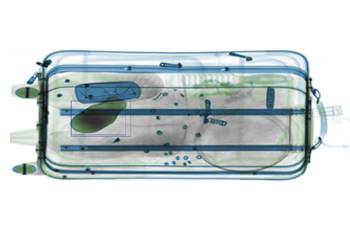

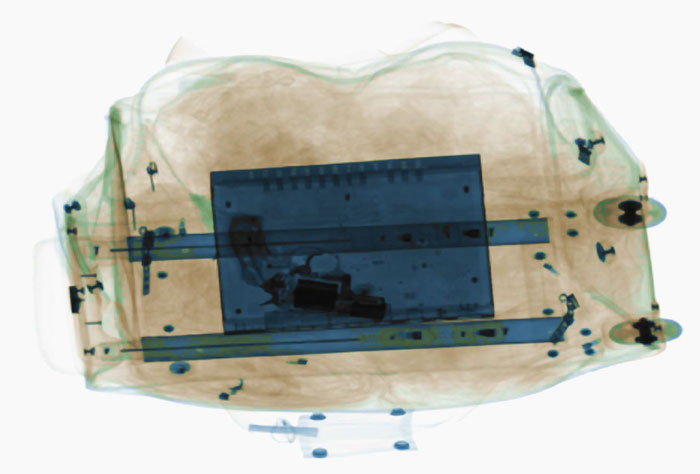

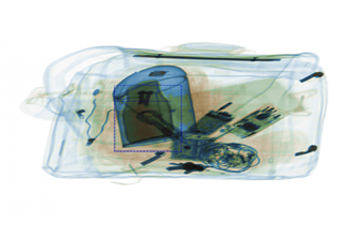

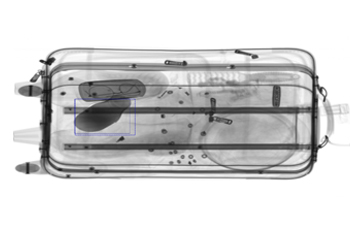

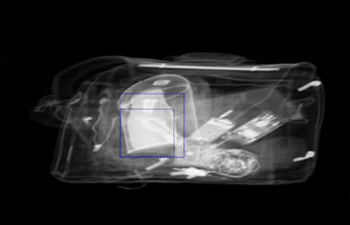

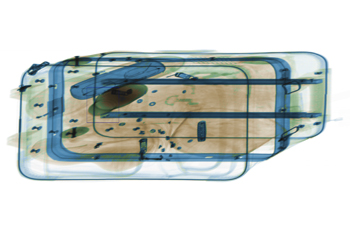

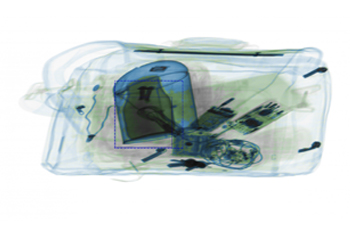

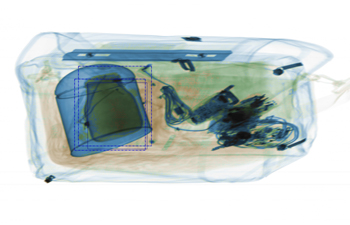

SENTINEL® CT checkpoint baggage inspection system is a 4th generation platform that utilizes an exclusive automatic material discrimination process to create multiple material discrimination ‘signatures’ to identify substances and articles of interest. ScanTech employs a multi-axes biopsy approach to analyze items utilizing its proprietary CT based 3D Ray-Trace Biopsy™ suite of algorithms. Scanned baggage and articles are first segmented into numerous ‘areas of interest’ followed by projecting granular volumetric biopsies from multiple and unique planar axes to determine if a known threat signature is present. If a 3D biopsy determines the examined area is a potential threat, additional biopsies are created to validate the threat signatures and create a visible colored boundary and alarm denoting the threat type and location. Threatening & non-threatening items and materials are clearly identified, color-coded, and annunciated on an Ultra-High Definition monitor. In addition, the system operator can manipulate and enhance the scanned images to pinpoint the location of any threat or contraband item for security support personnel intervention.

Sentinel Artificial Intelligence: How it Works

Virtual Sentinel, ScanTech’s proprietary AI application, utilizes an algorithm that creates synthetic data indistinguishable from actual scans. Machine learning processes real world and synthetic data to create vastly improved outcomes.

Virtual Sentinel Model & Synthetic Data accurately replicate material and configuration scenarios not captured during live data collection contributing to superior algorithm development and associated upgrades.

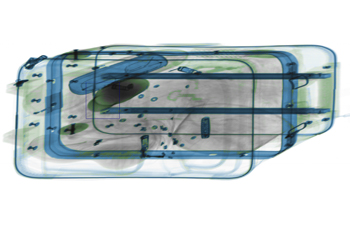

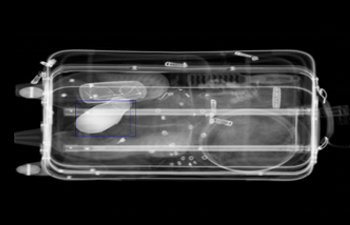

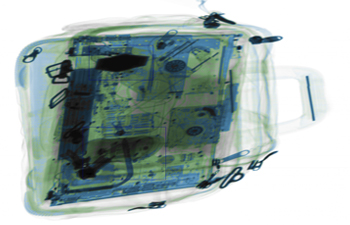

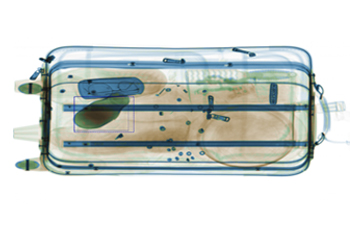

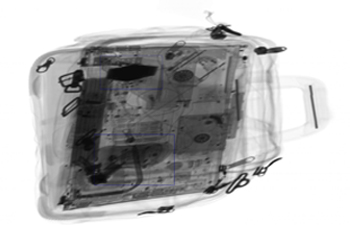

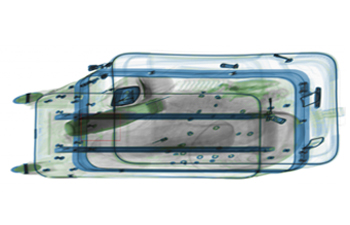

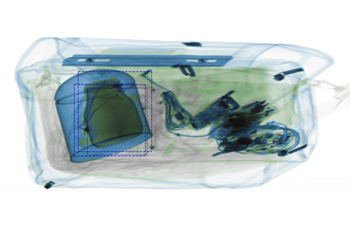

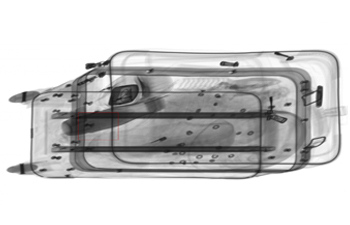

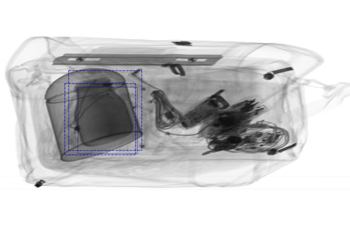

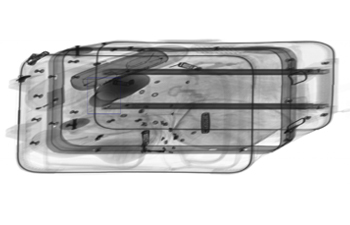

SENTINEL® CT SCANNED IMAGES

**Images above feature simulated explosives and weapons**

TUNNEL DIMENSIONS

25.5 (W) x 16.75 (H) inches or 647.7 (W) x 425.45 (H) mm

OVERALL DIMENSIONS

131 (L) x 59 (W) x 65.3 (H) inches or 3327.4 (L) x 1498.6 (W) x 1658.62 (H) mm / (max weight 4500 lbs or 2041 kg)

POWER REQUIREMENTS

120 or 240 VAC +10%/-15%; 50/60HZ; 3 kVAmax (USA); Other International electrical requirements are also available

SCANNING VIEWS

Fixed-Gantry CT with Four (4) independent scanning planes yielding Three (3) discrete dissection Axes:

- Axis #1 – Perpendicular to the Belt;

- Axis #2 – Off-Angle down the Belt viewed from Entrance;

- Axis #3 – Off-Angle down the Belt viewed from Exit

MATERIAL DISCRIMINATION

Automated Material Discrimination (color-coded and annunciated)

PENETRATION

35 mm of steel

THROUGHPUT

800+ bags/parcels per hour

X-RAY GENERATORS

Four 80 to 170kV X-ray monoblocks (hermetically sealed)

ALL SECURE® Multi-Energy Cargo Inspection Systems

For large cargo applications, ScanTech has designed and developed its high-energy ALL SECURE® scanning system utilizing Quad-Energy 3-10MeV X-ray generators. In this advanced material discriminating inspection system, X-rays are generated from Electron Beam Accelerators that pulse four (4) different X-ray energy spectrums between 3MeV to 10MeV. ScanTech’s Advanced Multi-Energy inspection technology with proprietary QUADRAD™ Multi-Energy Material Discrimination is the most advanced inspection technology of its type in the world. Using multi-energy X-Ray physics with variable energy propagation from multiple X-Ray sources, ScanTech ALL SECURE® automatically locates, detects, identifies, and differentiates materials of interest hidden inside large cargo containers. ALL SECURE® can detect nuclear & radioactive materials, drugs, weapons, explosives, and other forms of contraband.

SENTINEL® and ALL SECURE® scanning systems are engineered to automatically locate, discriminate, and identify threat materials and items of interest at checkpoints in airports, seaports, borders, embassies, corporate headquarters, government & commercial buildings, factories, processing plants, and other facilities where terrorism and prohibited items are a possibility. Whether the scanned target is sheet explosives inside baggage or harmful material inside a 14-inch thick steel container, ScanTech has inspection systems that can project through the barrier to detect, identify, precisely locate, and discriminate materials of interest inside. From suitcases, briefcases, and packages to 53-foot ISO shipping/transport containers and semi tractor-trailer rigs, ScanTech has a non-intrusive inspection solution to meet Homeland Security needs and requirements.